Number One Quality Product Manufacturers In Sri Lanka

Number one manufacturer of coconut husking machines domestically and worldwide. It is considered as a product beyond the blacksmith industry and we have an experienced team of workers. Specially we export our machines to all over the world. And we have more than 2500 local customer base. We usually offer free consultations before purchasing machinery. Sisira Engineering Pvt Ltd is a company that manufactures coconut-related products and machines such as Coconut Husk Chips Single Side Machine, Coconut Husk Chips Double Side Machine, Coco Peat (Powder) Machine, Multi Chopper (Compost) Machine, Wood Cutter Machine, Animal Feed Mixure Machine etc.

The Benefits of Coco Peat, Coconut Chips, and Coconut Husk Machine Manufacturing

The manufacturing of machines that process coconut coir products—coco peat, coconut chips, and coconut husk—has significantly impacted agriculture and sustainability. These products, derived from the fibrous husk of coconuts, are valuable for various applications, providing numerous benefits to both agriculture and the environment. The advancement in machinery for processing these coir products has enhanced their availability and utility, fostering sustainable practices.The manufacturing of machines that process coconut coir products—coco peat, coconut chips, and coconut husk—has significantly impacted agriculture and sustainability. These machines are pivotal in converting the fibrous husk of coconuts into valuable products that serve a wide range of applications, from horticulture to environmental management.

Some of our company’s products use coconut husk

- Coconut Husk Chips

- Chips Size 4s(small)

- Chips Size 7mm

- Chips Size 9mm

- Chips Size 10mm

- Chips Size 20mm

- Chips Size 22mm

- Chips Size 25mm (Large)

2. Coco Peat Compost

- High water holding capacity

- Acceptable pH & EC

- Excellent wettability, superior to peat

- Ability to retain nutrients against leaching and to buffer supply

- Unique water holding capacity

- Good drainage / aeration

- Less shrinkage

- Retains physical properties longer

- Light weight

3. Coco Peat Grow Bag

- Grow bags have become a popular choice for multipurpose growing medium for vegetables, fruits & flowers.

- Grow bags contains 100% natural coco peat.

- Grow bags are made up of a special blend of coir pith and chips, designed to provide the ideal air to water ratio for hydroponics.

- Ready to use bags make it ideal for harvesting and replanting.

4. Coco Peat Disk

- Rich in potassium and a number of micro nutrients.

- Neutral pH.

- Holds moisture incredibly well; easy to re-wet when it dries out.

- Change the Product style “Coco Net Plugs”.

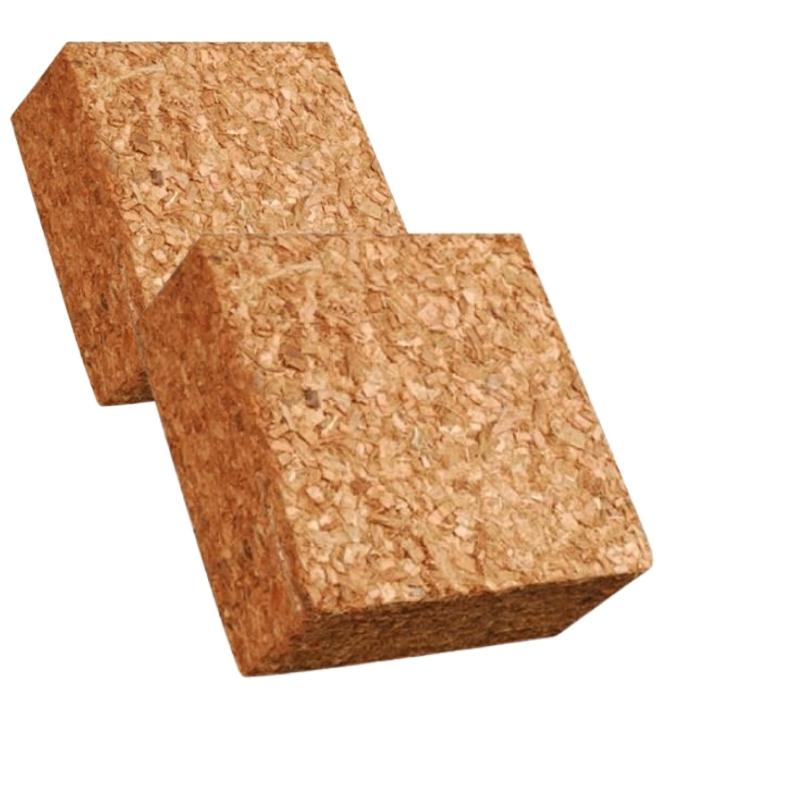

5. Coconut Husk Chips Blocks

-

Size 30 cm x 30 cm x 12 cm –14 cm

- Particle Sizes S1: 15 mm, S2: 10 mm

- Compression 4:1 or 5:1

- EC > 0.7 ms / cm

6. Square Coco Peat Blocks

- Packaging Type : Pallet

- Packaging Size : 5kg Block

- Form : Block

- Shape : Square

- Color : Brown

- Use for : Nurseries & Greenhouses

7. Rectangular Coco peat Blocks

- Size: 20X10X5CM ± 2mm

- Weight: 650g ± 50g

- Compression Ratio: 5:1

- Packing : Palletized with shrink film

- PH: 5.2 to 6.8

8. Coco Fibre

- Its cellular structure makes it weaker and more elastic than other natural fibres.

- Its cellular structure makes it weaker and more elastic than other natural fibres,

- The cell walls of fiber and pith contain more lignin than any other commercially relevant natural fiber, including wood. Lignin is a natural polymer, which adds strength and elasticity to the cellulose-based fiber walls.

Export New Items

Export types of machinery

New Customers Reviews

Ruchira Chandrasekara

Customer

“Engineering place

Tractor repair

Specially animal feed meals service and productions”

Janaka Rathnayaka

Customer

“We ordered coconut husk chips in SriLanka. Sisira Enginering company had a best quality. That is why We continuously order.”

Amila Prasad

Customer

“There are a lot of machines on the market. I just searched good coconut husk chipping machine in our country. Unfortunately, I wouldn’t be able to find a good machine. So, I paid for a machine from sisira engineering . Finally I could find and get the best machine.”

We are exporting our machines all over the world

India

Philippines

Thailand

vietnam

pakistan

Seashell

Maxico

Maldives

Gahana