Coconut Double side Chips Machine + Conveyor Belt Machine + Sieving Machine system

Original price was: රු820,000.00.රු800,000.00Current price is: රු800,000.00.

Coconut Husk Chips Cutting Machine – Double side with conveyor Belt – Sieving Machine . This machine can be used to cut coconut husk and make husk chips. . Coconut husk chips are used to make plants. Here in this machine you can use this to make coco husk chips.In the world most countries have coconuts such as India, Philippines, Malaysia, Brazil, Indonesia, Sri Lanka, etc

In Stock

DESCRIPTION

INTRODUCTION OF MACHINE - MADE BY SISIRA ENGINEERING (PVT) LTD

Sisira Engineering (pvt) Ltd is a company which located in Sri Lanka Kurunegala district. As a company, We have more than 20 years of experience in the field machine manufacturing. Some of them are coconut husk chips cutting machine, coco peat machines, coconut powder machine, Multi chopper machine, Multi choper long machine and much more…

INTRODUCTION OF COCONUT DOUBLE SIDE CHIPS MACHINE WITH CONVEYOR BELT MACHINE - SIEVING MACHINE - MADE BY SISIRA ENGINEERING (PVT) LTD

COCONUT HUSK CHIPS CUTTING MACHINE – DOUBLE SIDE

What are the features of Coconut husk chips machine

- Safety – Before working with a machine, the employee should be safe from the running parts. In our machine there are good safety things such as electrical system, motor guard, belt guard and much more

- Nice finishing

- Quality of coconut husk chips

- Any type husk can be cut – There are many type of coconut husks. But some machines cannot be used for cutting husk using dried husks. In our chips machine you can cut any type of coconut husks.

- Good durability – To keeping customer’s trust, We always use high quality materials for making the machine.

- Motor Capacity – 3HP and 2HP induction motors are included in double side machine. The motor can be single phase motor or three phase motor. It depends on the requirements you need.

- Steel blades are fixed

- No need to sieve again from a raisy net – Our machine’s output has a great quality. You should never sieve chips using a raisy net.

- We offer all of accessories

- High Speed – RPM is 1450. You can cut 6000 husks per 8 hours.

- Easy adjustable – The chips size can be adjustable from 5mm to 25 mm

OVERVIEW OF COCONUT HUSK CHIPS MACHINE (DOUBLE SIDE)

- Color:Blue (Legend)

- Weight: 350 KG single machine

- Motor: 2 HP motor, 3HP motor

- Materials: Steel, alloy steel, iron, PI, etc

- Chip sizes: 7mm, 8mm, 10mm, 20mm, etc

- Condition: Brand New

- Country of Origin: Sri Lanka

CONVEYOR BELT

A conveyor belt is a looped belt that is driven by and wrapped around one or more pulleys. It is powered by an electric motor and supported by a metal plate bed or rollers upon which the conveyor belt rests. The pulley that powers a conveyor belt is referred to as the drive pulley and has an unpowered idler pulley.

Pulley drives at the discharge end of a conveyor belt are referred to as head drives, while ones located at the infeed end are known as tail drives. The preferred type of pulley drive is a head drive located at the discharge end and uses pull force to move a conveyor belt.

There is an endless number of types and uses for conveyors. All of the varieties serve the purpose of transporting materials and goods along a continuously moving path. Though motorized conveyor belts are the traditional form of a conveying system, some systems use rollers without a motor to move materials.

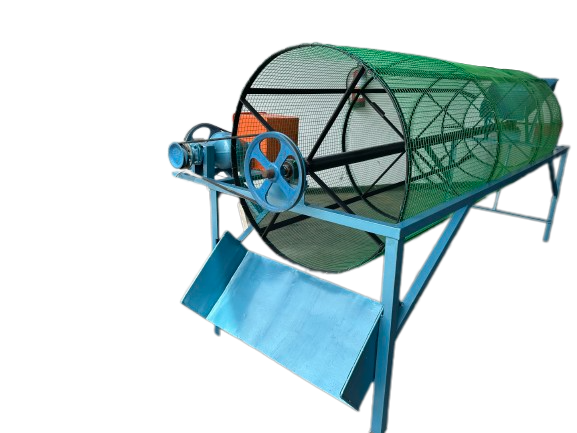

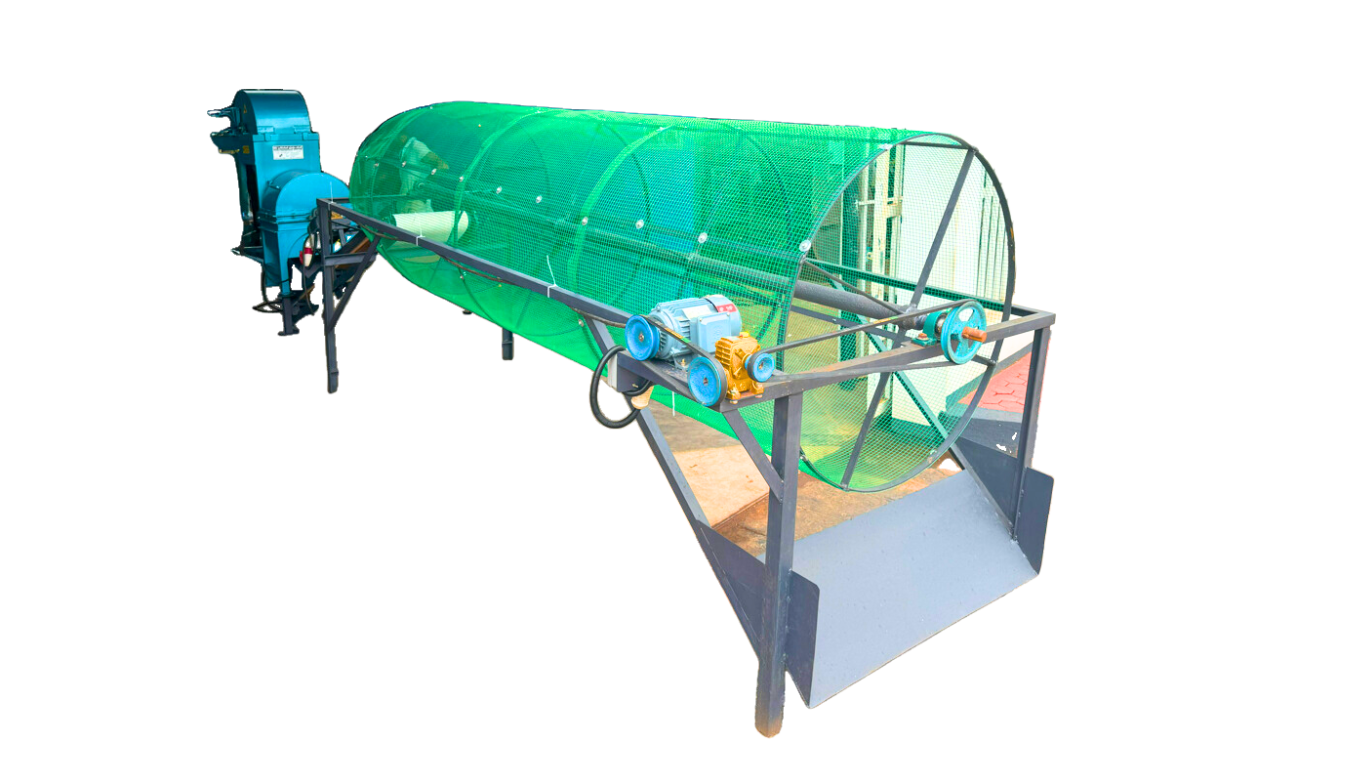

SIEVING MACHINE

What are the features of Sieving machine

A sieving machine, also known as a sieve shaker or vibrating sieve, is a device used to separate particles or granules based on their size or composition. Here are the key features of a typical sieving machine:

- Vibrating Mechanism: Sieving machines use a vibrating or oscillating mechanism to create motion in the sieve, allowing particles to move and separate.

- Sieve Surface: The machine typically consists of one or more sieve surfaces, which can be made of mesh or perforated material. Different sieve sizes or types can be used for various applications.

- Size Selection: Sieving machines come with multiple sieve sizes or screens, allowing users to select the appropriate mesh size to achieve the desired particle separation.

- Adjustable Settings: Many sieving machines offer adjustable settings for vibration intensity and duration, enabling precise control over the sieving process.

- Hopper or Feeder: Some sieving machines have a hopper or feeder to introduce the material into the sieve uniformly.

- Collection Tray: Sieved material is collected in a tray or container, making it easy to retrieve and analyze the separated particles.

- Safety Features: These machines often have safety features like a transparent cover or guard to prevent accidents and dust emissions.

- Portability: Some models are portable and compact, making them suitable for use in various locations within a facility.

- Easy Maintenance: Sieving machines are designed for easy cleaning and maintenance, with removable screens and accessible components.

- Material Compatibility: Sieving machines can be constructed from various materials, including stainless steel, to suit the compatibility requirements of different substances.

- Digital Controls: Advanced sieving machines may include digital controls and displays for precise control over the sieving process and data recording.

- Customization: Depending on the application, sieving machines can be customized to accommodate specific requirements, such as higher capacity or specialized sieving techniques.

OVERVIEW OF SIEVING MACHINE

- Color: Mix color

- Motor: 1HP

- Materials: Steel, alloy steel, iron, PI, etc.

- Powder sizes: Any

- Condition: Brand New

- Country of Origin: Sri Lanka

Call Now : +94776893935

WhatsApp : +94776893935

Related Products

Get In Touch

Reviews

There are no reviews yet.